Optical Ipad BGA Rework Machine

Optical ipad bga rework machine 1. Quick preview: Dinghua DH-A2E BGA rework station are equipped with superior safety Functions and emergency protection for safety issue.Moreover,with multi-funtion and innovative design, Dinghua machine can make one-stop Romoving,Mounting and Soldering. Welcome...

Opis

Optical ipad bga rework machine

1. Quick preview:

Dinghua DH-A2E BGA rework station are equipped with superior safety Functions and emergency protection for

safety issue.Moreover,with multi-funtion and innovative design, Dinghua machine can make one-stop Romoving,

Mounting and Soldering. Welcome to pay a visit to our factory and have a look.

1. Specification

Specification | ||

1 | Total power | 5300w |

2 | 3 independent heaters | Top hot air 1200w, lower hot air 1200w, bottom infrared preheating 2700w |

3 | Voltage | AC220V±10% 50/60Hz |

4 | Electric parts | 7" touch screen + high precision intelligent temp control module + stepper motor driver + PLC + LCD display + high resolution optical CCD system + laser positioning |

5 | Temperature control | K-Sensor closed-loop + PID automatic temp compensation + temp module,temp accuracy within ±2℃. |

6 | PCB positioning | V-groove + universal fixture + movable PCB shelf |

7 | Applicable PCB size | Max 370x410mm Min 22x22mm |

8 | Applicable BGA size | 2x2mm~80x80mm |

9 | Dimensions | 600x700x850mm (L*W*H) |

10 | Net weight | 70 Kg |

2.Product Features and application of the DH-A2E BGA rework station

DH-A2E BGA Rework Station Main Features:

Main Features:

◆ Multi-functional ergonomic system

① bottom heater can be adjusted up and down.

② Adopted all kinds of magnetic top and bottom nozzles, with 360° rotation, easy for installation and replacement,

customized sizes are available.

③ Multi-functional PCB support shelf, can be moved along X axis, together with universal fixture and V-groove brac-

ket, suitable for all kind of PCB positioning.

◆ Superior safety functions

Machines are CE certification guaranteed. It is equipped with emergency button. Also there is voice warning around

5 seconds before soldering/desoldering process complete. With automatic power-off protection device when abnor-

mal accident happens, with a double over-heating protection control.

DH-A2E BGA Rework Station Application

This machine is used for repairing the broken BGA (Ball Grid Array package) chipset on the PCB motherboard.

BGA application

1. Laptop & desktop PCBA

2.Game console,such as Xbox one,Play Station 4

3.Mobile phone PCBA

4.TV&TV Set-top box motherboard

5.Server ,Printer,Camera etc motherboard

4.Detailed Images of A2E BGA REWORK STATION

3. Company Profile

About us

Some pictures of our factory and BGA rework station

Offices

Manufacturing lines

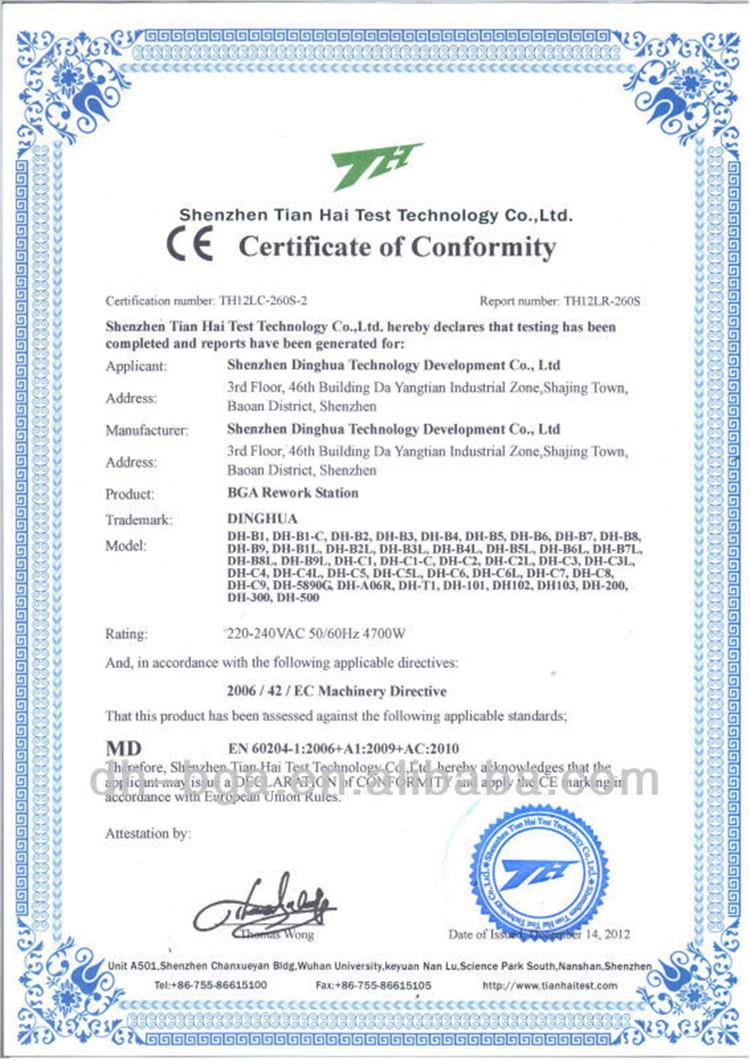

CE Certification as below

Part of our Clients

6. Packing & Delivery & Services of DH-A2E BGA REWORK STATION

7. FAQ

Q: Are you trading company or manufacturer ?

A: We are factory with more than ten years manufacturing and foreign tradeing, and also one of the biggest workshop

in this industry in China, also have our own R&D engineering team.

Q: What is the payment way ?

A: We accept the payment terms: Bank transfer, WesterUnion,,Paypal, etc.

Q: What is BGA chip repairing steps?

A: 1) Taking off the BGA chipset from the PCB motherboard,it is called desoldering.

2) Cleaning the Pad.

3) Cleaning and Reballing the BGA or replace a new one directly ---need to use reballing kit and accessories

4) Positioning the BGA chipset ---BGA rework station with optical alignment camera could help you position easily and

efficiently.

5) Soldering the BGA chipset on the PCB.